As former President Donald Trump advocates for heightened tariffs in a bid to bolster American industry, his sons are actively involved in a new venture focused on “revitalizing” U.S. manufacturing. The firm, centered on reshoring production and strengthening domestic supply chains, reflects a continuation of the Trump family’s economic agenda amidst ongoing debates over trade policy and its impact on the nation’s industrial landscape. This initiative underscores the intersection of political influence and private enterprise in shaping the future of American manufacturing.

Trump’s Tariff Strategy Targets US Manufacturing Growth

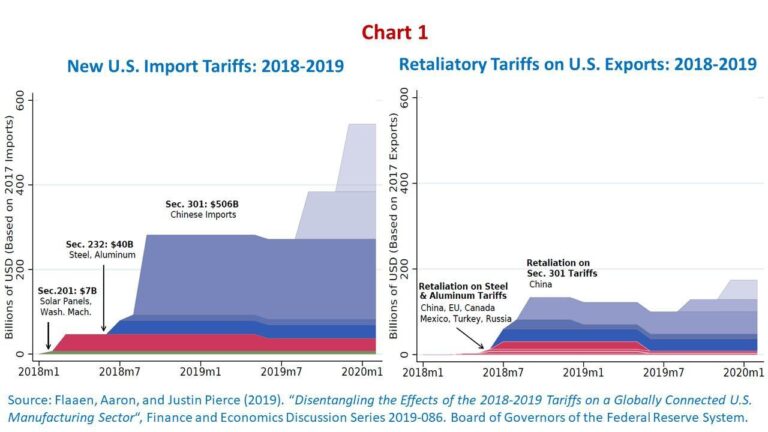

Under the Trump administrationŌĆÖs tariff initiatives, a new wave of policies has been introduced with the explicit goal of stimulating the resurgence of American manufacturing. These tariffs, primarily targeting imported steel and aluminum, aim to protect domestic producers from overseas competition deemed “unfair,” while encouraging companies to invest more directly in U.S.-based production facilities. The strategy is a calculated economic maneuver designed to safeguard jobs, bolster industrial output, and reduce reliance on foreign supply chains. Observers note that these measures have sparked both support and controversy among economists and business leaders alike, balancing immediate costs against potential long-term gains in American manufacturing capacity.

Parallel to these tariff efforts, Trump’s sons have taken tangible steps by backing a newly founded firm with a mission to revitalize the U.S. manufacturing sector. This enterprise focuses on leveraging tariff-driven opportunities to attract investment, innovate production techniques, and enhance workforce skills. The company sees tariffs not just as a shield, but as a catalyst for creating a more competitive and self-sustaining industrial landscape. Key initiatives include:

- Fostering partnerships between local suppliers and manufacturers

- Investing in advanced manufacturing technologies

- Promoting sustainable and energy-efficient factory operations

| Metric | Pre-Tariff (2017) | Post-Tariff (2023) |

|---|---|---|

| U.S. Steel Production (million tons) | 86 | 101 |

| Manufacturing Employment (million) | 12.5 | 13.3 |

| Domestic Investment ($ Billion) | 48 | 62 |

Role of TrumpŌĆÖs Sons in Driving Revitalization Efforts

Donald Trump’s sons have emerged as pivotal players in advancing a business initiative aimed at rejuvenating the deteriorating state of American manufacturing. Their involvement comes as the former president champions aggressive tariff policies designed to protect domestic industries from foreign competition. By publicly backing a firm dedicated to reshoring production, they are positioning themselves at the intersection of political influence and industrial strategy, seeking to turn geopolitical tensions into tangible economic benefits.

- Strategic leadership: Acting as executive members, Trump’s sons are steering company objectives focused on U.S.-based manufacturing expansion.

- Policy synergy: Their efforts align closely with broader administration goals on trade and economic nationalism.

- Investment focus: Prioritized sectors include steel, automotive, and electronics to revive key employment bases.

| Role | Responsibility | Impact |

|---|---|---|

| Executive Oversight | Guiding firmŌĆÖs strategic initiatives | Increases US factory output |

| Public Advocacy | Promoting tariffs and reshoring | Boosts investor confidence |

| Networking | Engaging policymakers | Secures favorable trade policies |

Impact of Tariffs on Domestic Industrial Competitiveness

Tariffs have become a double-edged sword for the US industrial sector, aiming to shield domestic manufacturers from foreign competition but also risking retaliatory measures and increased production costs. While proponents argue tariffs provide a vital boost to American industries by making imported goods more expensive and less attractive, critics note that rising input costs have forced many firms to reconsider their operational strategies. Some manufacturers face higher prices for raw materials and components, which can stifle innovation and reduce their ability to compete globally.

Industry leaders acknowledge both opportunities and challenges arising from tariff policies. Key impacts include:

- Supply chain disruptions: Seeking to avoid tariff penalties, many companies are relocating suppliers or investing in domestic alternatives, leading to transitional turbulence.

- Increased domestic investment: Higher tariffs have prompted reinvestment in US factories, aligning with revitalization goals championed by policymakers.

- Export uncertainty: Retaliatory tariffs from trade partners have created unpredictability for exporters, complicating long-term planning.

| Sector | Positive Impact | Negative Impact |

|---|---|---|

| Steel & Aluminum | Increased domestic demand | Higher costs for downstream manufacturers |

| Automotive | Encouraged local assembly | Rising price of imported parts |

| Electronics | Potential growth in reshoring efforts | Limited domestic supply chain capacity |

Policy Recommendations to Strengthen American Manufacturing

To catalyze the resurgence of American manufacturing, policymakers must embrace a multifaceted approach. Investing in advanced manufacturing technologies such as automation, AI, and robotics can boost productivity while keeping American firms competitive globally. Equally critical is expanding workforce development initiatives aimed at equipping workers with the skills needed to thrive in a modern factory setting, including apprenticeships and vocational training programs. These efforts should be paired with strengthening supply chain resilience to reduce dependency on foreign sources for critical components.

Further, targeted incentives can invigorate domestic production by offsetting costs associated with reshoring and modernization efforts. Key policy actions include:

- Tax credits for companies investing in U.S.-based manufacturing facilities

- Enhanced R&D subsidies to foster innovation in core industries

- Trade enforcement measures to ensure fair competition and prevent dumping

| Policy Area | Expected Impact | Timeframe |

|---|---|---|

| Technology Investment | 15%-20% productivity increase | 3-5 years |

| Workforce Development | Reduced skills gap by 30% | 2-4 years |

| Tax Incentives | Increase reshoring by 10% | 1-3 years |

In Retrospect

As President Trump continues to advocate for tariffs aimed at boosting American manufacturing, the involvement of his sons in leading a firm dedicated to revitalizing the sector adds a new dimension to the evolving economic landscape. Whether these efforts will translate into sustained job growth and industrial resurgence remains to be seen, but the administrationŌĆÖs focus on reshaping trade policies underscores the ongoing debate about the best path forward for the U.S. manufacturing industry.