In an exclusive report, POLITICO Pro unveils the mounting challenges faced by American businesses operating in China amid the ongoing US-China trade tensions. Companies caught in the crossfire of former President Donald TrumpŌĆÖs tariff policies describe a landscape marked by uncertainty and constraint, with many feeling ŌĆ£trappedŌĆØ as they navigate a complex web of duties and regulatory hurdles. This article delves into how these tariffs continue to reshape the operational realities for US firms in China, highlighting the broader economic and diplomatic ramifications of sustained trade protectionism.

Trump Tariffs Strain US Businesses Operating in China Amid Growing Economic Uncertainty

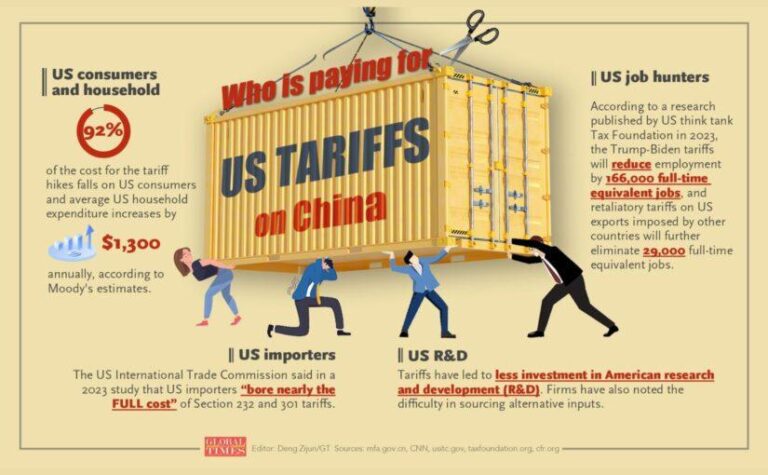

US companies entrenched in the Chinese market are increasingly voicing concerns over the fallout from tariffs imposed during the Trump administration. These levies, initially intended to recalibrate trade imbalances, have instead created a complex web of financial strain and operational challenges. Executives describe a scenario where they face escalating costs, disrupted supply chains, and reduced competitiveness ŌĆō all while navigating a regulatory environment that remains unpredictable amid growing geopolitical tensions.

Key issues impacting US businesses in China include:

- Increased cost of raw materials and manufacturing inputs due to layered tariffs

- Disrupted supplier relationships causing production delays and inventory shortages

- Limited options to pivot operations without incurring significant relocation expenses

- Heightened scrutiny from Chinese regulators, compounding operational difficulties

| Category | Impact | Business Response |

|---|---|---|

| Supply Chain | Delays & rising costs | Source alternate suppliers locally |

| Tariff Costs | Up to 25% increase | Absorb costs or raise prices |

| Regulatory | Increased compliance checks | Hire additional legal support |

Supply Chain Disruptions and Cost Pressures Challenge American Companies in Key Chinese Markets

American companies operating in crucial Chinese markets have encountered escalating challenges as supply chain disruptions compound the financial strain caused by enduring tariffs. The ongoing trade tensions, marked by Trump’s tariff policies, have forced many businesses into a precarious position where adjusting their supply lines is neither swift nor cost-effective. These firms face rising costs not only from tariff payments but also from increased logistics expenses, delays, and raw material shortages. For industries heavily reliant on just-in-time manufacturing, such disruptions have led to compromised production schedules and constrained profitability, reinforcing an atmosphere of uncertainty.

Key factors exacerbating these pressures include:

- Tariff entanglement: Escalating import duties on essential components raise operational expenses.

- Transport bottlenecks: Congested ports and limited freight capacity delay delivery times.

- Labor shortages: Fluctuating workforce availability disrupts manufacturing continuity.

- Currency volatility: Fluctuations in exchange rates impact cost forecasting and pricing strategies.

| Impact Area | Challenge | Business Response |

|---|---|---|

| Raw Materials | Price spikes and scarcity | Sourcing diversification |

| Shipping | Delays and port congestion | Inventory buffer increase |

| Tariffs | Imposed import taxes up to 25% | Production relocation exploration |

| Labor | Availability instability | Automation investment |

Navigating the Tariff Maze Strategies for US Firms to Mitigate Financial Risks and Maintain Competitiveness

US firms entrenched in China face an increasingly complex web of tariffs that disrupt supply chains and elevate costs, forcing companies to rethink traditional strategies. To navigate this challenging environment, businesses are adopting a multifaceted approach, balancing short-term financial mitigation with long-term competitiveness. Key strategies include diversifying manufacturing bases to countries with fewer trade restrictions, aggressively leveraging duty drawback programs, and renegotiating supplier contracts to share the financial burden. These tactical moves help alleviate immediate tariff impacts while preserving relationships critical for global operations.

Key Strategic Responses:

- Supplier diversification: Expanding sourcing to Southeast Asia and Mexico to bypass tariffs.

- Financial hedging: Utilizing currency and commodity hedges to offset cost volatility related to tariffs.

- Inventory management: Adjusting stock levels to optimize cash flow and reduce tariff exposure.

- Local production investments: Increasing onshore manufacturing capabilities to serve the US market directly.

- Policy engagement: Collaborating with trade associations to influence tariff policy and seek exemptions.

| Strategy | Benefit | Challenge |

|---|---|---|

| Supply Chain Diversification | Reduced tariff burden | Complex logistics |

| Duty Drawback Programs | Tax refunds on re-exported goods | Paperwork and tracking |

| Local Manufacturing | Tariff avoidance | Higher operational costs |

Policy Recommendations Urge Reassessment of Trade Measures to Support Bilateral Business Stability

Recent analyses underscore the urgent need for policymakers to reconsider existing trade barriers that have entrenched challenges for American firms operating in China. Business leaders advocate for a strategic rollback of tariffs that have inadvertently restricted supply chain fluidity and escalated costs, ultimately undermining bilateral economic stability. Key recommendations emphasize:

- Implementing phased tariff reductions to ease financial pressure on US companies abroad

- Enhancing diplomatic dialogue focused on trade predictability and transparency

- Supporting multilateral frameworks to address unfair trade practices

- Facilitating targeted relief programs tailored to sectors most affected

Evidence suggests that current trade measures have not only suffocated American exporters but also contributed to a market environment where uncertainty hampers strategic investment decisions. A comparative overview reveals the tangible effects of tariff policies on operational costs and market access:

| Impact Area | Pre-Tariff Period | Post-Tariff Period |

|---|---|---|

| Average Export Costs | $120/unit | $180/unit |

| Supply Chain Delays | 5 days | 12 days |

| Market Access Index | 85/100 | 60/100 |

Concluding Remarks

As the ramifications of Trump-era tariffs continue to ripple through the global supply chain, U.S. businesses entrenched in China face mounting challenges with limited options for relief. Industry leaders and policymakers alike grapple with balancing economic interests against geopolitical tensions, underscoring the complexity of untangling trade barriers that have reshaped decades of multinational cooperation. The path forward remains uncertain, as companies navigate a fraught landscape seeking stability amid persistent tariffs that, for many, feel like a trap rather than a tactic.